Dot peen marking

Marking with a needle embosser – forgery-proof, durable and flexible

Materials of most different shapes (no matter if round or flat) can be marked with a special needle. A distinction must be made between the following marking methods: Needle embossing and needle scribing.

In needle embossing (also called impact point method), the material is marked with a hard metal tip (needle) oscillating by compressed air, which is moved in X and Y direction during its up and down movements.

This causes a dense sequence of individual points (lettering) to be pushed into the material. The carbide tip hits the workpiece shortly before its lower reversal point. This compresses or displaces material in the workpiece, creating a point on the workpiece. During needle embossing, the marking consists of a dense sequence of individual points that form a closed line. Alternatively, if desired, a font can be selected in which the dots are embossed so far apart that a dotted font is created instead of a closed line.

During needle embossing, marking depths of up to 0.7 mm can be achieved. The distance between the carbide tip and the workpiece is up to 10 mm. Since the carbide tip oscillates, material unevenness of up to 6 mm can be compensated. This means that your markings can still be read after powder coating or painting.

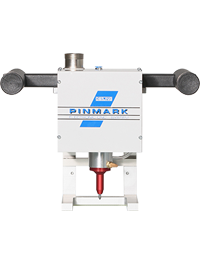

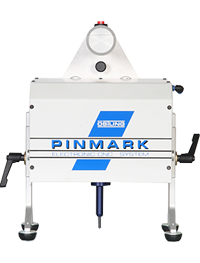

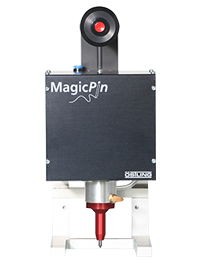

The marking tool with carbide tip is fixed in the marking head, the so-called stamping head. A stamping head has 2 linear axes as standard, which are driven by toothed belts.

Any characters, numbers, logos and 2D codes (DataMatrix) can be embossed within the marking field during needle embossing.