Controls

for needle embossers and scribers

from Östling Marking Systems

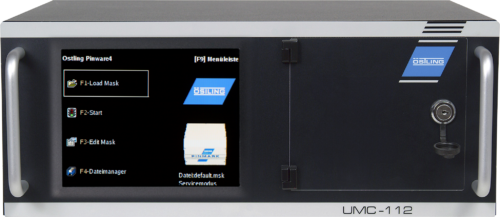

The control unit UMC 112 is used to control all our needle embossers and scribers of the PinMark – series.

This device sends all types of marking data to the end systems. This marking data includes, for example:

- 2D codes (DataMatrix)

- Serial numbers

- Company logos and other graphics

- All other conceivable product data

Data that can be changed, such as date, time, batch number, material composition, etc., are automatically generated by the controller according to predefined criteria.

Various interfaces make it possible to send the corresponding information to the controller beforehand. Using a barcode scanner, for example, employee and extensive material information can be scanned in and later embossed onto the product as a compact 2D code (this is just one of many examples).

The use of the Embedded Linux operating system generates four benefits for you:

- Microsoft Windows™ license costs not applicable

- User-friendly, intuitive interface

- Special solutions for special requirements easier to implement

- Highest stability in everyday industrial use