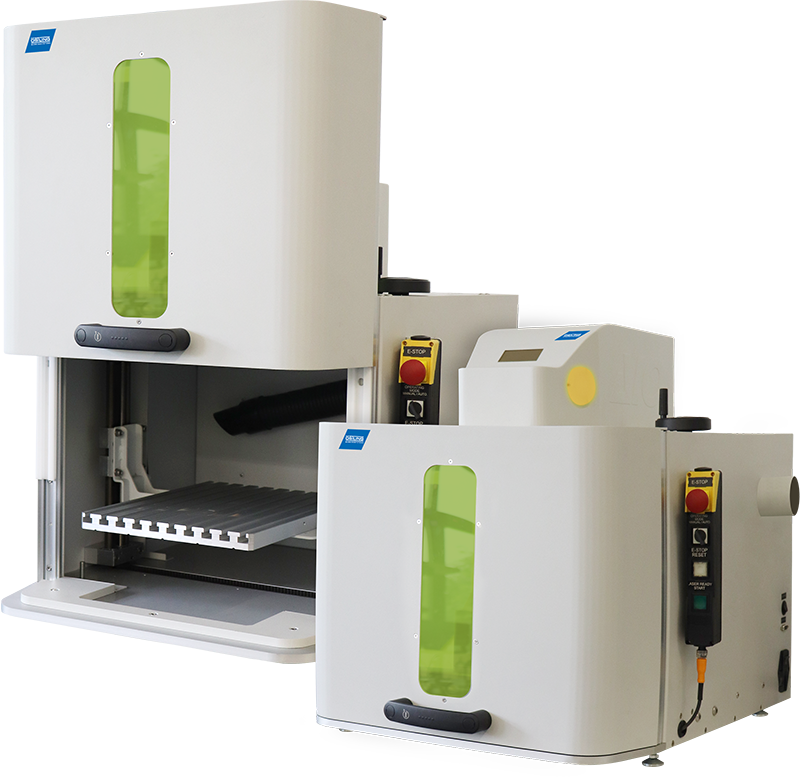

The compact “ALL IN ONE” laser station

Highlights

[table id=72 responsive=scroll responsive_breakpoint=device /] Plug and Play

Plug and Play

The AIOBox is a “Plug and Play” laser station. It can easily be connected to a PC via USB or network cable (LAN) and is immediately ready for use. The AIOBox is very easy to commission and easy to assemble, making it a convenient model. Despite its compact design, the AIOBox has an exceptionally large loading volume. Depending on the lens used, a marking area of up to 200 x 200 mm can be used.

The AIOBox is equipped with two separate safety circuits and meets the requirements of the Performance Leve l e (PL e) according to EN ISO 13849-1.

The laser is safely switched off when the sliding door is opened and an emergency stop device is also provided.

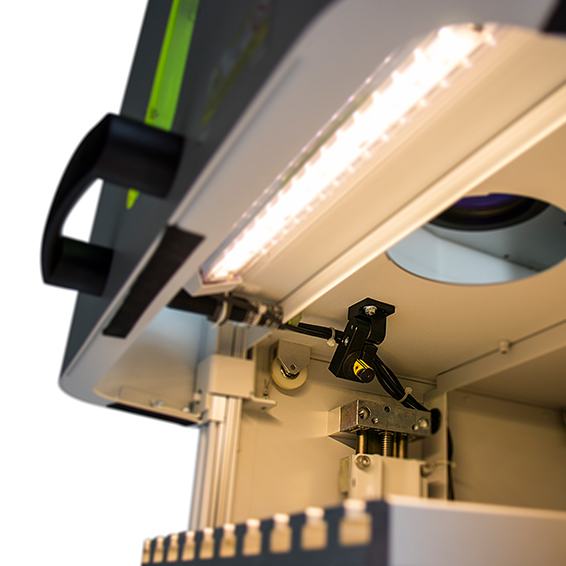

The extraction system is standard on all AIOBox variants and the focus aid/pointer is available on all models.

For a clear view, the AIOBox is illuminated from the inside with LEDs.

The AIOBox is compact and extremely quiet, so that you can use the laser station undisturbed in the office or in a quiet environment.

With the proven XS Designer software, automated markings such as serial numbers, 2D codes (DataMatrix), etc. can also be easily implemented.

Simple and compact

The AIO laser is the most compact Q-switched DPSS laser. AIO laser systems are offered in a robust and lightweight monoblock design and enable a wide variety of marking applications that are also suitable for micromachining.

The “All In One” monoblock design eliminates the need for external optical fiber and other sensitive cable connections for system integration. Optionally, the AIOBox can also be extended if you want to mark larger workpieces, for example.

The simple and reliable integration, even in confined spaces, is another advantage of the AIO laser system.

Further features

Laser safety glass

Laser safety glass

Laser safety glass windows for safe setup and observation Highest security

Highest security

Two safe inputs up to PL e (Cat. 4) acc. to EN ISO 13849-1 Quality

Quality

Unsurpassed flexibility with high quality Cooling

Cooling

Thermoelectric air cooling Laser diode

Laser diode

Extremely long service life of the laser diode Development

Development

Many system components from our own development OEM

OEM

OEM models and complete solutions available Software

Software

User friendly software under Windows XP / 7 / 8 / 10 Special engineering

Special engineering

In-house special machine construction exactly adapted to your needs

- Different housing variants for complete solutions

- Rotation axes for round parts, so that the processing distance and laser beam are always perfectly and precisely aligned with the object to be marked.

- Height axes in all possible designs (manual, electric, pneumatic, fully automatic)

- Axis control UMC box Laser for controlling two additional functions, such as height axis and positioning axis. The rotary indexing table and magazine can also be controlled. With this optional laser accessory, cycle times for laser marking can be greatly reduced.

- Barcode scanner for practical reading and activation of data to be marked

- Camera systems for automatic machine reading of previously marked data such as 1D, 2D and DataMatrix codes (Please have a look at our information on HIBC and GS1)

- Lenses for various applications / marking field sizes and workpieces / materials

- Spare parts of all kinds for our marking lasers

- Laser safety goggles for different wavelengths available on request

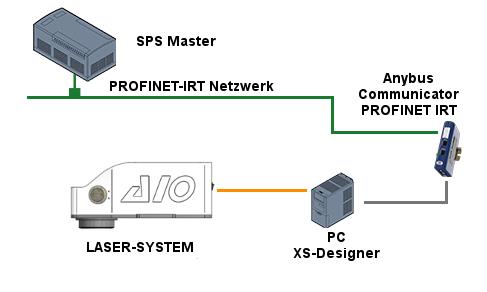

Anybus Communicator PROFINET IRT

With the Anybus Communicator you can integrate serial devices (RS-232/422/485) into a PROFINET-IRT network. The Anybus Communicator is a proven and reliable protocol converter that connects non-networked devices to PROFINET-IRT. The Communicator performs intelligent protocol conversion and provides the serial data of the higher-level PLC as I/O data. The Communicator is a compact stand-alone gateway for IP20 and DIN rail mounting that requires a 24-volt power supply. It complies with the current PROFINET-IRT specification and has been successfully tested for network compatibility.

More information about laser accessories can be found here.

![]()

The XS Designer software combines marking software, CAD editor, parameter and interface management, sequence programming and diagnostic tools. This Windows-based marking software makes laser technology easy to master.

The XS Designer software combines marking software, CAD editor, parameter and interface management, sequence programming and diagnostic tools. This Windows-based marking software makes laser technology easy to master.

Further information about the XS Designer software can be found here.