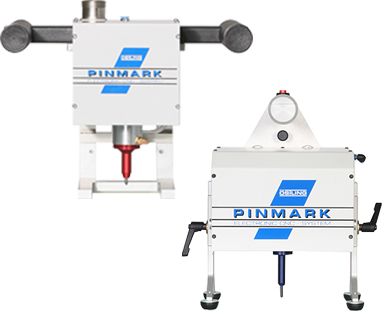

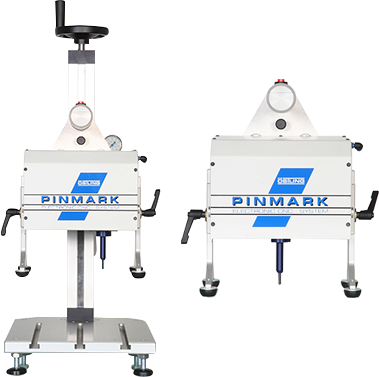

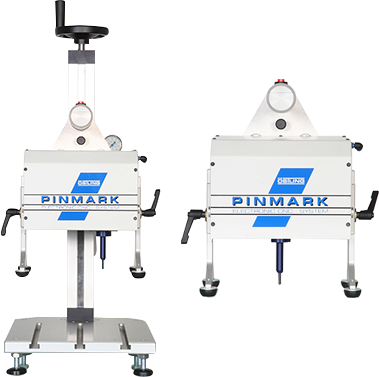

Combination carrier as table & hand embosser

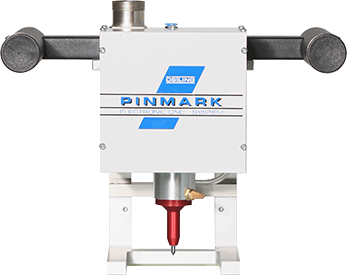

The PinMark combination carriers are table-top devices, especially suitable for metal marking of small series and individual items.

The usual robust and compact design makes it possible to create extremely precise markings on products and components.

Benefit from the freedom of a handheld device and the stable precision of a desktop device.

In just a few simple steps, the table-top device becomes a hand marker, which can be used to mark objects that are difficult to handle due to their size or weight. The embossing head is held against the object to be marked. The marking process is then triggered via the switch integrated in the handle.

The PinMark combination carriers differ mainly in the size of the respective marking field. In the following you can view the technical data of the respective models in short form.

Needle embossing accessories for needle embossing systems, needle embossers and needle scribers

We have a complete range of accessories available for you so that you can exploit the full potential of your marking system for metal marking. Here are some examples of the needle marker-/score range:

For more information about needle embossing accessories, see here.