Mark maximum

[table id=”74″ responsive=”scroll” responsive_breakpoint=”device” /]With its large interior, the LaseMax offers plenty of space for almost any application.

Components up to 1100 x 800 x 650 mm (L x W x H) and up to 200 kg can easily be marked with the large LaseMax laser marking station. Depending on the lens used, a marking area of up to 300 x 300 mm can be used.

The easy commissioning and the convenient mounting due to interior lighting and automatic safety door make it an absolute comfort model. The touch display and the professional marking software XS-Designer make it easy to realize automated markings, such as serial numbers, 2D codes (DataMatrix), etc.

ÖSTLING offers you the highest possible security with the laser marking station LaseMax. Laser safety glass for Safe setup and monitoring of the marking process, safe shutdown in accordance with EN ISO 13849-1 and the integrated extraction system are standard features. This is rounded off by the sturdy construction made of sheet steel suitable for industrial use.

Thanks to its large interior, the LaseMax offers the greatest possible flexibility for its applications. It is available with a wide range of options and different laser sources (power levels and wavelengths). Rotation axis and vision systems for code and position recognition are just some of the almost unlimited possibilities.

The LaseMax is a stand-alone laser marking station that is also ideal for integration into a production line.

We offer an extensive range of accessories for our various laser marking systems. With various options you can extend the functions of our marking lasers. Below are some examples of our comprehensive range of accessories in the laser area:

- Various housing variants for complete solutions

- Rotation axes for round parts, so that the machining distance and laser beam is always perfect and precise to the object to be marked

- Height axes in all possible versions (hand, electric, pneumatic, fully automatic)

- Axis control UMC box laser for controlling two additional functions, such as height axis and positioning axis. But also rotary table and magazine are controllable. This optional laser accessory greatly shortens the cycle times of laser marking.

- Barcode scanner for practical reading and activation of data to be marked

- Camera systems for automatic machine reading of previously marked data such as 1D, 2D and DataMatrix codes (Please take a look at our information on HIBC and GS1)

- Lenses for various applications / marking field sizes and workpieces / materials

- Spare parts of all kinds for our marking lasers

- Laser safety goggles for different wavelengths available on request

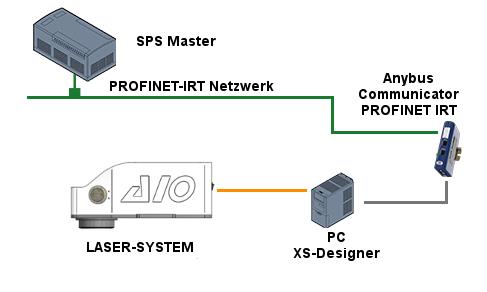

Anybus Communicator PROFINET IRT

With the Anybus Communicator, you can integrate serial devices (RS-232/422/485) into a PROFINET IRT network.

The Anybus Communicator is a field-proven and reliable protocol converter that connects non-connected devices to PROFINET IRT. The Com-municator performs an intelligent protocol conversion and makes the serial data of the higher-level PLC available as I/O data.

The Communicator is a compact stand-alone gateway for IP20 and hat rail mount that requires 24 volt power supply. It meets the current PROFINET IRT specification and has been successfully tested for network compatibility.

More information about laser accessories can be found here.

The XS Designer software combines labeling software, CAD editor, parameter and interface management, flow programming and diagnostic tools. This Windows-based labeling software makes laser technology easy to control.

The XS Designer software combines labeling software, CAD editor, parameter and interface management, flow programming and diagnostic tools. This Windows-based labeling software makes laser technology easy to control.

What can the XS Designer do?

The XS Designer software allows the creation of graphical files that serve as the basis for laser marking. The complete laser software package consists of the following components:

- USB laser control card (LazeCard); integrated in the laser

- USB/Ethernet driver of the laser control card (LazeCard); depending on the model

- ActiveX, COM server, VBS,… Interfaces

- Laser Control control program for setting the system parameters

- Graphics editor XS Designer to create projects that are passed to the laser

More information about the XS Designer software can be found here.