Semi-automatic systems

Highest quality from Östling.

Made in Germany

FLOWETCH semiautomatic systems

For direct and permanent marking of products with electrically conductive surfaces

The Flowetch is a semi-automatic marking system. The product to be marked is placed on the marking head and pneumatically pressed into place. The marking is then carried out on the underside of the respective product.

The marking is effected by a current pulse which is guided through the embossing of a stencil. This creates an exact image on the product to be marked.

The permanent electrolyte flow cools down the stencil and the material, making the stencils more durable.

The Flowetch consists of the following components: marking controller EU PULSE, mechanics (electrolyte basin and reservoir, stand, product holder), pneumatics and electrolyte pump. In addition to the standard version Flowetch , compact versions from our large product range are also available on request.

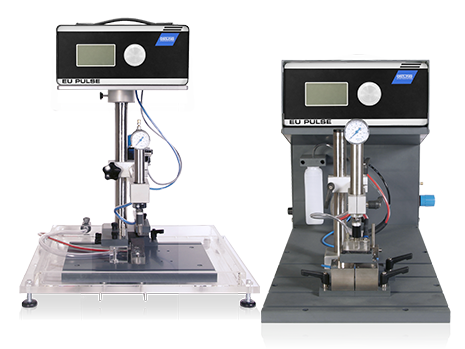

FLOWETCH Compact

FLOWETCH Compact

The FLOWETCH Compact is a semi-automatic marking system that marks products from below. This means that the product to be marked is placed on the marking head and pneumatically pressed into place. The marking is then carried out on the underside of the product.

The marking is carried out by a current pulse which is guided through the embossing of a template. This creates an exact image on the product to be marked.

The FLOWETCH consists of the following components marking controller EU PULSE, mechanics (electrolyte basin and reservoir, stand, product holder), pneumatics and electrolyte pump. In addition to the standard version FLOWETCH, compact versions are also available. The FLOWETCH Compact has a control system and mechanics integrated in a plastic housing.

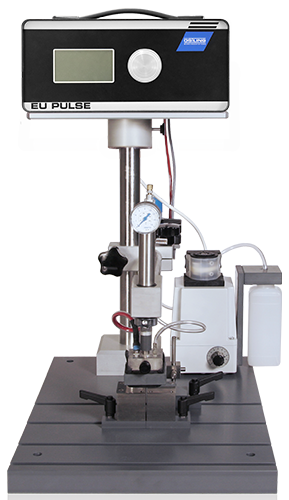

The EMP (Semiautomatic Marking System with Pneumatics)

The EMP (Semiautomatic Marking System with Pneumatics)

The EMP is a semi-automatic marking system with which the products are marked electrolytically from above.

The electrolytic marking process is conveniently triggered by a foot switch, whereupon all previously stored parameters (e.g. power, marking time, electrolyte pump…) are then automatically used.

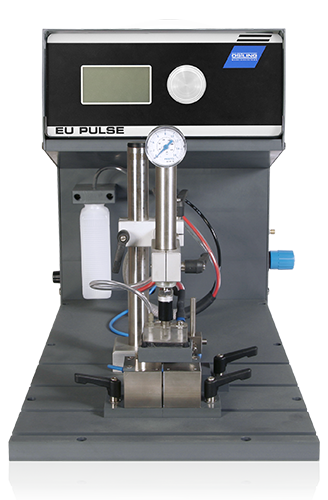

The “Modulmat” is a compact, semi-automatic marking device for electrolytic marking of products from above

The “Modulmat” is a compact, semi-automatic marking device for electrolytic marking of products from above

This is the compact version of the EMP (Electrolytic Marker with Pneumatics). Marking control and mechanics are integrated in one housing.

The electrolytic marking process is conveniently triggered by a foot switch, whereupon all previously stored parameters (e.g. power, marking time, electrolyte pump) are automatically used.

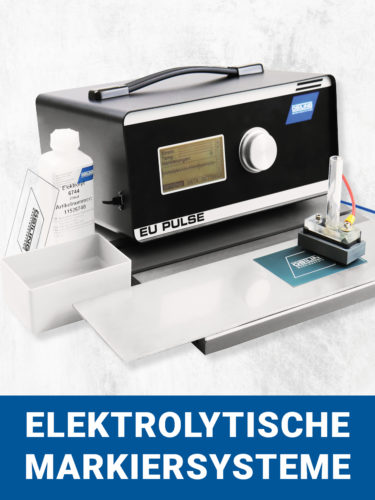

Electrolytic accessories – Everything you need for electrolytic marking is available from us.

From own production of Östling – Quality Made in Germany.

Whether you are looking for a manual workstation, a semi-automatic system or a fully automatic solution, you will find it difficult to confront us with a problem that we have not already solved in the electrolytic field.

We have all the accessories you need for a wide variety of product shapes, sizes and other requirements.

Electrolytic marking is still a very clever and cost-effective solution for achieving first-class and durable marking results quickly and elegantly with simple means.

Further information about electrolytic accessories can be found here.