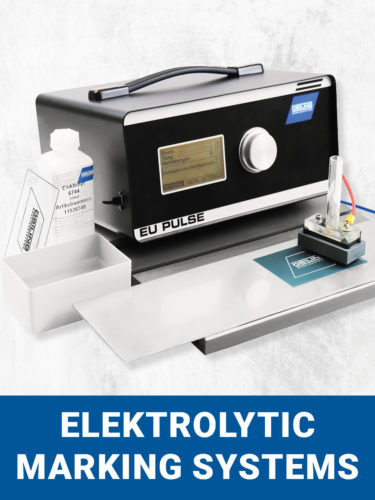

Electrolytic

Marking Systems

The Östling Original

Electrolytic marking systems – Electrolytic marking is based on an electrochemical marking process (so-called electrochemical metal marking), in which the text or image is permanently transferred to an electrically conductive product by means of a signing stencil by the action of electrolytes and current. Even though this is often referred to as etching, we do not use acids or other hazardous substances!

Östling offers you two different variants of signing templates. For each application we will find a suitable method for you with our short term templates and our long term templates. Further electrolytic accessories, such as felt, conductive net and marking heads are also available from us.

Electrolytic marking systems from Östling are cost-effective and ensure durable and high-quality markings on almost all electrically conductive materials such as aluminium, zinc, chrome, carbide, steel, stainless steel, titanium and many more. If your material is not included, please contact us.

The exact image of a stencil is applied to an electrically conductive product by combining current and electrolyte.

Depending on the surface material (or its composition) and current flow, black or white or deep markings are produced in interaction with our signing templates. No material removal takes place with light or dark markings. This process is therefore ideal for markings in the air and space as well as medical/ and food technology.

There are almost unlimited graphic possibilities with electrolytic marking systems from Östling. There are almost no limits to the size of the marking. From the injection needle to container marking, this process has been used for decades.

We have a large number of our own electrolytes available for a variety of materials.

Strengths of the electrolytic ÖSTLING marking systems

Typical applications for electrolytic markings

Electrolytic accessories in the online shop

[fusion_products_slider picture_size=”fixed” cat_slug=”elektrolytische-markiersysteme” number_posts=”50″ carousel_layout=”title_below_image” autoplay=”no” columns=”4″ column_spacing=”” scroll_items=”” show_nav=”yes” mouse_scroll=”yes” show_cats=”yes” show_price=”yes” show_buttons=”yes” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” /]