ALL IN ONE laser system

From InfraRED to GREEN

Highlights

AIO is the most compact Q-switched DPSS laser for excellent laser marking. AIO laser systems are offered in a rugged and lightweight monoblock design and enable a wide variety of marking applications that are also suitable for micromachining.

The “All In One” housing design eliminates the need for external optical fibers and other sensitive cable connections for system integration. A further advantage of the AIO is its simple and reliable integration, even in confined spaces.

More than one USB or network connection to a standard PC is not required to control the AIO All-In-One laser systems. The AIO’s compact monoblock design combines resonator and laser source, eliminating both the rack and the fiber that usually connects the optics to the power supply. Communication is via either USB or Ethernet. The distance to the workstation can therefore be almost unlimited and the marking process can easily be spatially decoupled from the control. Compared to conventional laser systems, the industrial connection and integration has been considerably simplified.

The AIO is equipped as standard with two separate safety circuits for emergency stop and safety door and meets the requirements of Performance Level e (PL e / Cat. 4) in accordance with EN-ISO 13849-1. This enables safe and direct integration in a convenient manner.

The compactness, high insensitivity to interference and very user-friendly handling enable excellent operating flexibility and guarantee an optimum cost/performance ratio. With AIO laser systems, a wide range of materials can be marked in a simple and cost-effective way, for which several marking lasers would otherwise be necessary.

The high pulse peak power and excellent beam quality make AIO All-In-One laser systems the ideal partner for the most demanding industrial laser marking applications. AIO All-In-One laser systems can be used either at a manual workstation or as an integration component in an automated system.

Competitive in the fiber segment

The diode service life of the AIO series is in no way inferior to that of the fiber lasers, whereby in the case of maintenance only the change of the diode module is necessary. In contrast to this, the fiber system in most cases requires an exchange of the entire laser unit with a complete stop of the laser marking.

In addition to maintenance, the energy balance of the AIO laser is also particularly efficient.

The Östling AIO family is available in the variants AIO P, AIO M, AIO G and AIO G+. All AIO versions are pure air-cooled and do not require any additional water cooling.

Further features

Installation

Installation

Reduced installation effort, Systema 2 library and 3D STEP model available on request Interfaces

Interfaces

Galvanically isolated interfaces (I/O’s, USB, Ethernet), optional Profinet/ProfiBus integration Maintenance

Maintenance

Low maintenance, almost noiseless operation possible Quality

Quality

Unsurpassed flexibility with high quality Cooling

Cooling

Thermoelectric air cooling Development

Development

Many system components from own development OEM

OEM

OEM models and complete solutions available Software

Software

User-friendly software under Windows XP / 7 / 8 / 10 Special mechines

Special mechines

Precisely adapted to your needs through in-house special machine construction

For our various laser marking systems we have an extensive range of accessories available. With different options you can extend the functions of our marking lasers. Below are a few examples of our comprehensive range of laser accessories:

- Different housing variants for complete solutions

- Rotation axes for round parts, so that the processing distance and laser beam are always perfectly and precisely aligned with the object to be marked.

- Height axes in all possible designs (manual, electric, pneumatic, fully automatic)

- Axis control UMC box Laser for controlling two additional functions, such as height axis and positioning axis. The rotary indexing table and magazine can also be controlled. With this optional laser accessory, cycle times for laser marking can be greatly reduced.

- Barcode scanner for practical reading and activation of data to be marked

- Camera systems for automatic machine reading of previously marked data such as 1D, 2D and DataMatrix codes (Please have a look at our information on HIBC and GS1)

- Lenses for various applications / marking field sizes and workpieces / materials

- Spare parts of all kinds for our marking lasers

- Laser safety goggles for different wavelengths available on request

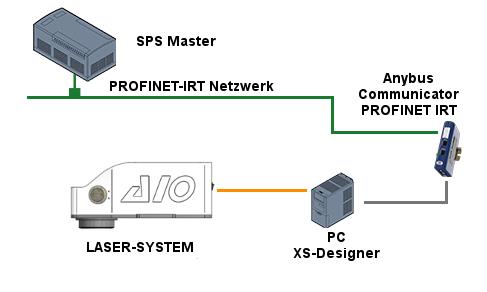

Anybus Communicator PROFINET IRT

With the Anybus Communicator you can integrate serial devices (RS-232/422/485) into a PROFINET-IRT network. The Anybus Communicator is a proven and reliable protocol converter that connects non-networked devices to PROFINET-IRT. The Communicator performs intelligent protocol conversion and provides the serial data of the higher-level PLC as I/O data. The Communicator is a compact stand-alone gateway for IP20 and DIN rail mounting that requires a 24-volt power supply. It complies with the current PROFINET-IRT specification and has been successfully tested for network compatibility.

More information about laser accessories can be found here.

![]()

The XS Designer software combines marking software, CAD editor, parameter and interface management, sequence programming and diagnostic tools. This Windows-based marking software makes laser technology easy to master.

The XS Designer software combines marking software, CAD editor, parameter and interface management, sequence programming and diagnostic tools. This Windows-based marking software makes laser technology easy to master.

Further information about the XS Designer software can be found here.